Advanced Liquid Cold Plate Technology for Optimal Cooling

Explore how our liquid cold plate solutions can enhance the thermal management of your advanced applications. Get in touch with us today to discuss your specific cooling requirements and discover the right liquid cold plate solution that aligns with your technical and budgetary needs. Let us help you achieve optimal performance with precision-engineered liquid cooling.

Our Liquid Cooled Heat Sink Solutions

Maximize your system's performance with our Liquid Cold Plate technology, offering advanced solutions for the most challenging cooling needs. Our plates ensure efficient thermal management, tailored to meet specific industry demands.

COMMON MATERIAL DATA SHEETS

Al-6061 Al-6063 Al-6360 Cu-110

-

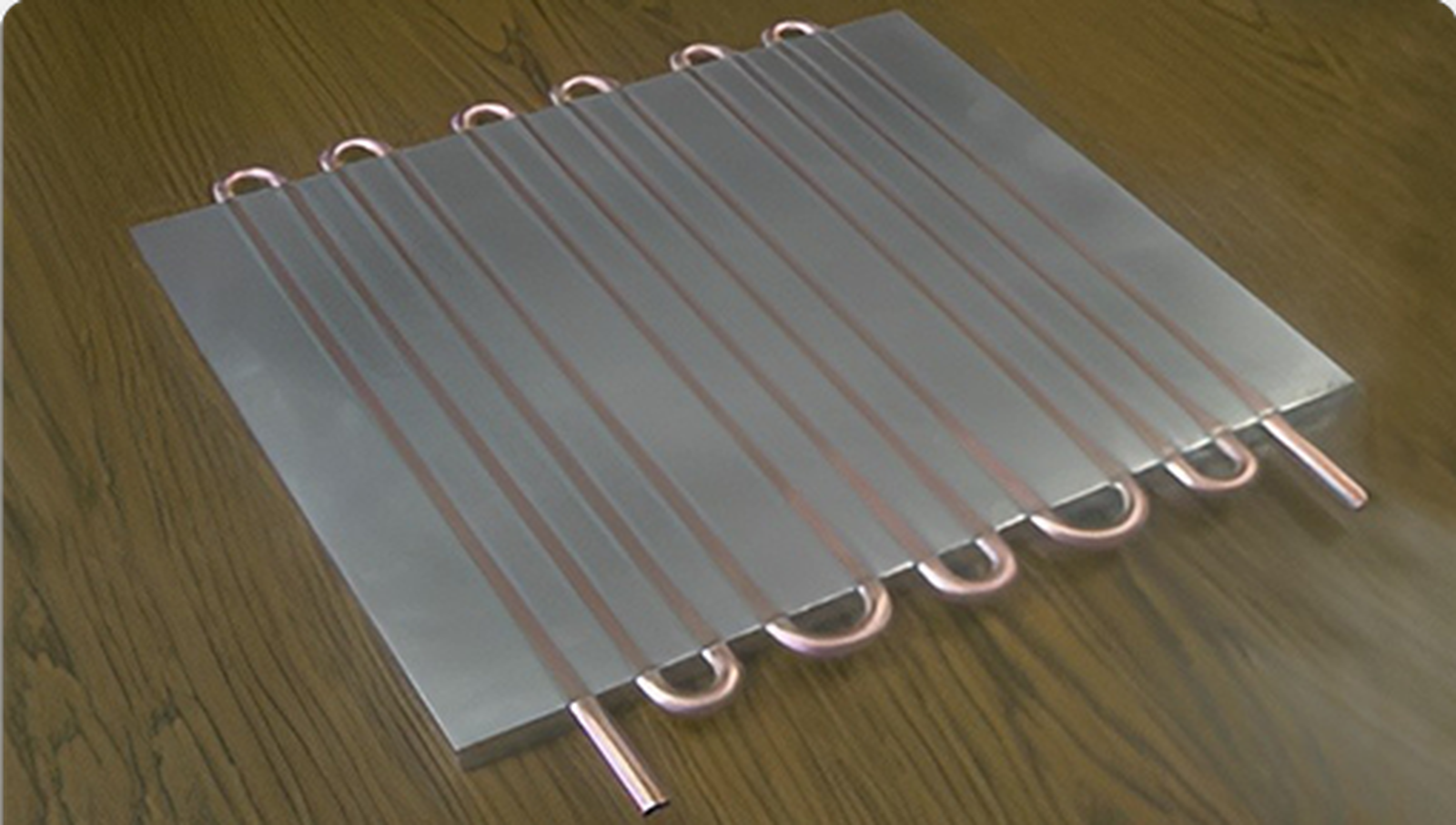

PRESSED-IN TUBE COLDPLATE

The Pressed-In Tube Liquid Cold Plate delivers exceptional performance at an economical price, making it an ideal choice for projects that require effective liquid cooling without a high cost. This liquid cold plate solution leverages simple yet robust design principles to achieve efficient heat transfer.

- Cost-Effective: Provides high-end cooling performance without the premium price tag.

- Efficient Heat Transfer: Utilizes a pressed-tube design to maximize contact with the cooling plate, enhancing thermal conductivity.

- Versatile Application: Suitable for a variety of industries, including automotive, energy, and industrial machinery, where liquid cold plates are essential.

-

HYPERCOOL COLDPLATE

Our Hypercool Liquid Cold Plate features advanced machined-in flow paths that offer limitless customization to meet specific cooling requirements. This flexibility makes it ideal for applications requiring precise thermal management solutions.

- Customizable Flow Paths: Allows for tailored configurations to optimize the Liquid Cold Plate's cooling efficiency for any application.

- High Precision: Machined flow paths ensure exact thermal management for critical components.

- Broad Compatibility: Adaptable to a wide range of industries, from electronic manufacturing to aerospace and defense.

- What is a Liquid Cold Plate, and how does it work?

- What are the primary advantages of using a Liquid Cold Plate?

- Can Liquid Cold Plates be customized for specific applications?

- How do I determine the right Liquid Cold Plate for my cooling needs?

A Liquid Cold Plate uses a conductive liquid, typically water or a water-glycol mixture, to transfer heat from a source to a radiator. This method is highly effective for managing high thermal loads in advanced applications.

The main benefits include superior cooling efficiency, precise temperature control, and the ability to handle significantly higher thermal loads compared to air-cooled systems.

Our Liquid Cold Plates can be tailored with specific materials, flow paths, and dimensions to meet your project's unique requirements, ensuring optimal performance.

Determining the right Liquid Cold Plate involves analyzing your system’s heat load, spatial constraints, and cooling requirements. Our engineering team collaborates closely with clients to gather these details and recommend the most suitable Liquid Cold Plate configuration for effective and efficient thermal management.